OTEC technology

OTEC is a clean technology for extracting energy from sea water, and the process

resembles geothermal heating. In addition to producing electricity, some of the

sea water running through an OTEC plant (the working fluid in an Open Cycle plant)

becomes desalinated, and can produce thousands of cubic meters of fresh water every

day. The OTEC process can be described as follows:

- Platforms are placed near a coastline with warm surface water (preferably 25 °C

or more as the process needs a 20 °C temperature difference in order to work and

the more the better), where cold deep-sea water is pumped to the surface using very

large pipes, about a thousand meter long and several meters in diameter. It is then

possible to transform the difference in heat energy to electricity through the use

of heat exchangers, compressors, turbines, and generators.

- Depending on the method used, surface water may become evaporated and in that way

turned into potable water of high quality.

- The needed temperature difference can be found in large areas of the tropics that

account for about a third of all ocean water. Still, OTEC has a low thermodynamic

efficiency; typically, less than 3 % of the energy extracted from the surface water

in OTEC goes into electricity. This is about a tenth or fifteenth of the efficiency

of an automobile engine, but on the other hand sea water is free, and petrol is

not only expensive but also hazardous to the environment. Using the sea water flow

in other processes as well (for aquaculture etc.) makes OTEC not only more usable

but also more economically feasible.

Below is a schematic of a proposed sea-based OTEC platform, generating 5 MW. Note

the size of the chairs and tables in the personnel quarters!

OTEC plants may be installed on-shore, but can also be constructed as floating platforms,

similar to oil platforms. Platforms in the sea means shorter distance to the deep

cold water, but requires a power cable to bring the electricity to shore, unless

the electricity is used altogether on the floating platform (for example, for producing

hydrogen compounds for the automotive industry).

OTEC systems can also be placed on ships ("grazing OTEC"), which can then travel

the oceans and run the OTEC process where the surface water is, for the moment,

at its warmest. The power generated can be temporarily stored on ship, and if using

big tankers for this process, potable water can be stored on board as well, to be

added to a nation’s water supply at a later point in time.

It’s noteworthy that working with the OTEC community is advantageous for stakeholders from other marine energy technologies, such as wave power or ocean-based wind power. The reason why is that OTEC platforms are so large that they can host other energy technologies, thus being turned into multi-purpose platforms. Moreover, a major expense for many marine energy technologies is storing the electricity. An OTEC plant already addresses this issue, so the cost of other maritime energy sources can be dramatically lowered using OTEC plants for storage of energy.

Other benefits from OTEC technology

Apart from producing nearly pollution-free energy, the sea water running through

the OTEC process can be used for a number of attractive purposes. One of these is

the ability to, after the automatic desalination, generate thousands of cubic metres

of fresh water per day, another to create nutritious areas for the fishing industry,

and a third one to cool buildings. For African countries such as Nigeria, Tanzania,

Mozambique, and Kenya, OTEC facilities should be very welcome, and as opposed to

the oil and gas industry, there is no risk for hazardous emissions: nothing is being

transported to the mainland but fresh water and electricity.

In an excellent introduction to OTEC as well as an often cited article, Dr. Luis

Vega discusses the various benefits of OTEC (Vega, L. A. (2002/2003). Ocean Thermal

Energy Conversion Primer. Marine Technology Society Journal, 6(4), pp. 25-35.).

Of most importance is electrical power and the production of fresh water, but there

are also byproducts such as sea water air conditioning (SWAC), the possibility to

bring nutrient water to enhance mariculture productivity, hydrogen production, and

the acquiring of trace metals.

In his keynote speech at the OTEC Africa Conference 2013, Dr. Ted Johnson showed

that just one 100 MW floating OTEC plant:

- provides base-load electricity for 100,000 people by producing 800 Million kWh per

year

- replaces 1.3 million barrels of oil each year, and in so doing, avoids the generation

of up to 800,000 tons of CO2 per year

- produces 120 million liters of fresh water per day

- moves four cubic km of high nutrient deep sea water each year, enough to grow 70

tons of shellfish meat each day.

In addition to what's pointed out above, OTEC can in the near or distant future

have many other uses. These are discussed in the Introduction to OTEC technology

chapter in the OTEC Matters 2015 publication. The most promising today are probably SWAC and gas production for the automotive industry:

- The cold deep ocean water can be led through pipes to establish sea water air conditioning

(SWAC). Doing SWAC as a simple byproduct of the discharging of deep sea water should

be a compelling argument to the OTEC advocators.

- It is not a trivial task to convert heat energy to electrical power in the middle

of the ocean and then transport this power to an onshore electrical grid. Aoften

more appetizing approach is to use the energy on the OTEC platform for other purposes,

such as for the production of different liquids or gases, which in turn can be used

for the automotive industry or other tasks. Currently, hydrogen gas production is

probably of most interest (challenged by ammonia).

To find out more about the many facets of OTEC, please refer to the OTEC Matters chapter.

Where OTEC works

In order for the OTEC process to work, a significant difference in temperature is

needed, and therefore, tropical areas (0 to 20 degrees north and south) are of the

main interest. As the facilities can be built on land, as platforms close to shore,

and as mobile solutions on large vessels, there are vast areas that can be used

for this technology, about 60 million square kilometres. According to calculations

performed in the mid 1990’s, facilities spread over this area should produce more

than seven times the energy consumption of the USA. The image below shows where

the temperature difference is the highest, thus providing the most efficient locations

for OTEC facilities. As far as OTEC Africa is concerned, the important region is

also marked in the project's logotype.

How OTEC works

There are two ways in which OTEC technology can work, called "open cycle" and "closed

cycle". OTEC works a bit like a refrigerator, and a complete understanding of the

two OTEC methods is not really important in order to appreciate the OTEC Africa

project. After all, the technology is proven to work and earlier problems that OTEC

have faced have been related to the cost-effectiveness of OTEC technology versus

the price of crude oil.

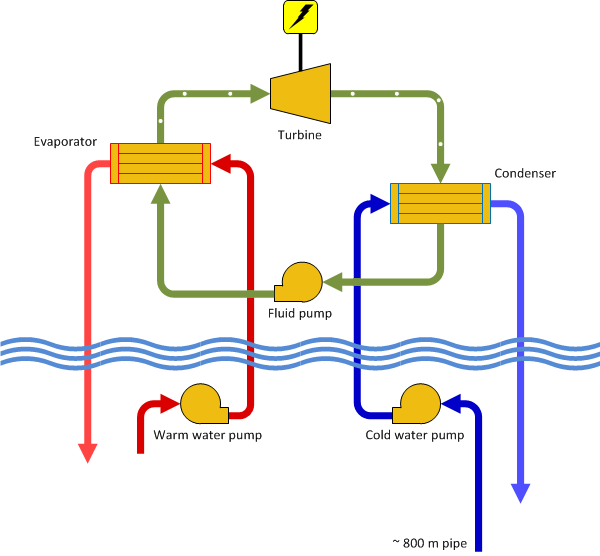

This is a sketch from Lockheed Martin displaying the closed-cycle OTEC process.

Below are more complex explanations and schematics over the two methods.

Closed Cycle OTEC

Warm surface water and cold deep sea water are used to vaporize and condense a working

fluid, such as ammonia, which drives a turbine and then a generator in a closed

loop, producing electricity. This method generates more electricity than the open

cycle method does, but it doesn’t generate fresh water.

Open Cycle OTEC

A chamber is filled with water from the surface. A pump creates a vacuum, thus lowering

the atmospheric pressure until the water starts to boil. (Pressure regulates the

temperature at which a liquid boils; a comparison can be made with a pressure cooker

for fast cooking at home, where high pressure makes the water hotter than 100°C

without starting to boil.) The resulting steam from the surface water – about 0.5%

of this water flow is sent into the chamber – is used to drive a turbine, which

in turn drives a generator. Cold deep sea water is used to condense the steam to

fresh water after it has passed through the turbine. In OC-OTEC there is, as the

name says, no closed loop. Instead, “new” water is retrieved from the surface. The

previously vaporized and then condensed water is now desalinated, thus turned into

fresh water.